Replacing NOx emulator NOXEM 129 | 130. Introduction

The procedure of replacing the NOx emulator is very simple and takes 10 to 15 minutes.

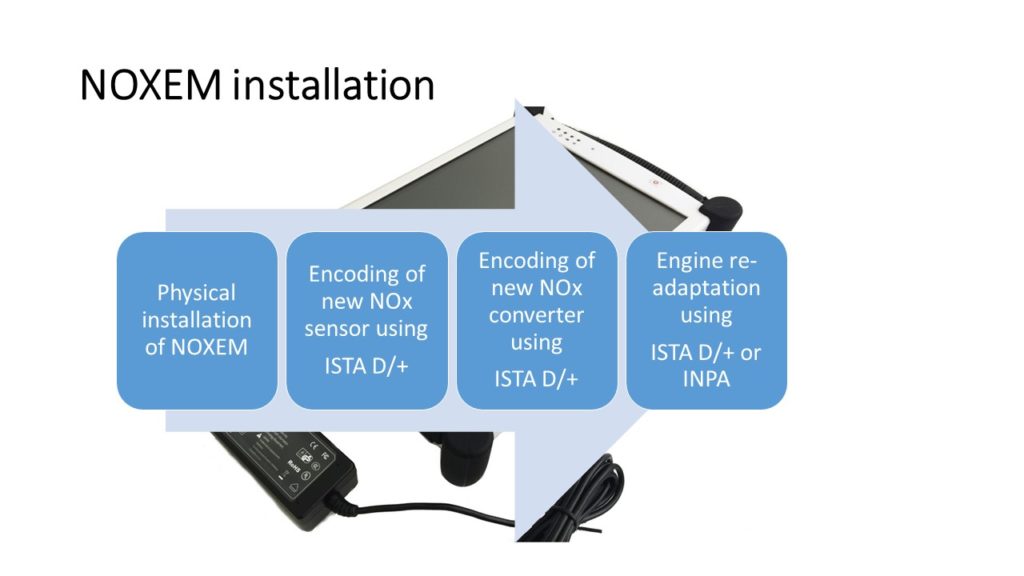

After replacing the NOx emulator, several service procedures have to be performed.

- Coding of replacement of the NOx catalytic converter using ISTA D/+ (can be skipped if 30E9 error is NOT stored AND re-adaptation of the engine using INPA is performed). The engine management system monitors the status of a NOx catalytic converter. Data on its short-term poisoning (with sulfur) and long-term deterioration are stored in the engine management unit. The engine management unit allows only long-term performance deterioration – this is self-explanatory. If insufficient long-term performance (error 30E9 stored) or poisoning (error 30EA) of the NOx catalytic converter is detected – after replacing the catalytic converter (real replacement or installation of NOXEM), the engine management unit has to be “informed” that the catalytic converter is replaced. Otherwise, the new catalytic converter will not be used because the engine management unit will be sure that the catalytic converter is still damaged/aged/poisoned. This procedure is also intended in regulations from BMW AG as a service procedure.

- Coding of replacement of the NOx sensor using ISTA D/+ (can be skipped if re-adaptation of the engine using INPA is performed). This procedure has to be performed as prescribed by BMW AG (in this case, it’s the replacement of the NOx emulator instead of the sensor). The NOx sensor reports to the engine management system several important parameters (content of oxygen in the exhaust, content of NOx, etc.), the engine management system processes the information and evaluates if the sensor readings are reliable and correct. It is critically important to update the “profile” of the sensor after replacement.

- Re-adaptation of the engine using INPA (recommended) or ISTA D/+. If the car has been driving for a while with a defective NOx system, the performance of the engine has been disturbed. The engine has used only one injection mode: Homogeneous injection (actually: emergency mode) from three possible modes; many service procedures (measuring of injector’s leakage and reaction time; equalization of the cylinder’s mechanical and chemical efficiency, etc.) are also disturbed, as mentioned here. After the installation of the NOx emulator and executing all procedures mentioned in No.1 & No.2 (if necessary), the engine should be re-adapted. This procedure is described in the entry “Installation of NOx emulator. Part 2”.

Attention! Do not use aerosol type spray (brake cleaner, WD40 and similar) during replacement of the sensor! The fume of these sprays can damage the sensor! Remove the protective cap from the sensor directly before installation. If a spray is previously used, dry the surface using compressed air for several minutes.

To perform all service procedures, you will need:

- ISTA D/+ (for encoding); critical if 30E9 error is stored

- INPA (recommended for re-adaptation)

Installing of NOXEM. Part 1 | Replacement; encoding (using ISTA D/+)

Installing of NOXEM. Part 2 | Re-adapting (using ISTA D/+ or INPA)

Important! For all owners of the N43/53 series engine (and N52/54/55 as well), we are recommending purchasing an ELM327 OBD diagnostics adapter. This is a cost-effective (starting from 10 EUR) solution with different connection (Bluetooth; Wifi; USB) options. With this adapter, you will see ignition quality (misfire counters) for each cylinder. If your engine has problems with ignition (partially damaged ignition coil, leaking injector, etc.), the situation may become worse when the Stratified charge is re-enabled. The burning of a lean mixture requires the maximal power of a spark; even the smallest current leakage or incorrect fuel beam can provoke misfires. With the ELM327 adapter, you will determine the misfiring cylinder within seconds!

Detailed information here.