11787587129

alternative NOx Sensor / emulator

11787587129 (actual release)

11787587128

11787582327

11787580518

11787576908

11787565447

Bottom of car, passenger side, access form the car’s bottom

BMW | E60 LCI, E61 LCI with N53 and N43 series petrol engine

BMW | E63 LCI, E64 LCI, E90, E90 LCI, E91, E91 LCI, E92, E92 LCI, E93, E93 LCI with N53 series petrol engine

- Rough idle (cold and/or hot engine)

- Uneven run at mid/high loads

- Misfires and error messages about misfires

- Error messages about cylinder’s and/or bank’s fuel trim

- Problems with cold engine start

- Increased fuel consumption

- Restores normal operation of NOx system and fuel economy

- DOES NOT require NOx catalytic converter replacement

- Restores creation of cylinders individual and bank fuel adaptations for idle, mid/high loads, cold engine – smooth operation at all conditions

- Restores Stratified charge and Homogeneous lean fuel injection modes, regeneration, and desulfation of NOx catalytic converter

- Increased lifetime: average more than 300’000 km

Reason for replacement

Following NOx sensor error messages

2AEC Nitrogen Oxide Sensor Self Diagnostics

2AF0; 2B05 nitric oxide sensor, heating

2AF2; 2B06; 2B09 nitric oxide sensor, Lambda linear

2AF4; 2B07; 2B0A NOx sensor, electrical

2AF6; 2AFB; 2B0B nitric oxide sensor, Lambda binary

2AF9 nox sensor, nox signal: coast mode check

2EAE NOx sensor message missing (timeout)

30D6 nitric oxide sensor, plausibility

30D8 NOx sensor, Sensor damaged

30DA NOx sensor, heating time

30DC nitric oxide sensor, heating

30DE NOx sensor – Lambdaprobe before catalyst, Korrelation

30E0 NOx sensor, Offset

30E2 nitric oxide sensor, thrust test

30E4 nitric oxide sensor, aging

30E6 nitric oxide sensor, dynamics

Following NOx catalytic converter error messages

30E9 nitric oxide catalytic converter, aging

30EA nitric oxide catalytic converter, sulphurized*

*if an error appears repeatedly and/or forced desulfurization is not possible/successful

Following live data

NOx concentration is 0 ppm**

(INPA data | NOx Sensor / Exhaust temperature menu) after:

- the engine is warmed up

- exhaust temperature is more than 220 oC

- driving speed exceeds 20 km/h for more than 2 min

**continuously or periodically: the sensor is damaged

11787587130

alternative NOx Sensor / emulator

11787587130 (actual release)

11787587127

11787582326

11787580517

11787576907

11787571263

Bottom of car, passenger side, access form the car’s bottom

BMW | E81, E81 LCI, E82, E87 LCI, E88, E90, E90 LCI, E91, E91 LCI, E92, E92 LCI, E93, L93 LCI with N43 series petrol engine

- Rough idle (cold and/or hot engine)

- Uneven run at mid/high loads

- Misfires and error messages about misfires

- Error messages about cylinder’s and/or bank’s fuel trim

- Problems with cold engine start

- Increased fuel consumption

- Restores normal operation of NOx system and fuel economy

- DOES NOT require NOx catalytic converter replacement

- Restores creation of cylinders individual and bank fuel adaptations for idle, mid/high loads, cold engine – smooth operation at all conditions

- Restores Stratified charge and Homogeneous lean fuel injection modes, regeneration, and desulfation of NOx catalytic converter

- Increased lifetime: average more than 300’000 km

Reason for replacement

Following NOx sensor error messages

2AEC Nitrogen Oxide Sensor Self Diagnostics

2AF0; 2B05 nitric oxide sensor, heating

2AF2; 2B06; 2B09 nitric oxide sensor, Lambda linear

2AF4; 2B07; 2B0A NOx sensor, electrical

2AF6; 2AFB; 2B0B nitric oxide sensor, Lambda binary

2AF9 nox sensor, nox signal: coast mode check

2EAE NOx sensor message missing (timeout)

30D6 nitric oxide sensor, plausibility

30D8 NOx sensor, Sensor damaged

30DA NOx sensor, heating time

30DC nitric oxide sensor, heating

30DE NOx sensor – Lambdaprobe before catalyst, Korrelation

30E0 NOx sensor, Offset

30E2 nitric oxide sensor, thrust test

30E4 nitric oxide sensor, aging

30E6 nitric oxide sensor, dynamics

Following NOx catalytic converter error messages

30E9 nitric oxide catalytic converter, aging

30EA nitric oxide catalytic converter, sulphurized*

*if an error appears repeatedly and/or forced desulfurization is not possible/successful

Following live data

NOx concentration is 0 ppm**

(INPA data | NOx Sensor / Exhaust temperature menu) after:

- the engine is warmed up

- exhaust temperature is more than 220 oC

- driving speed exceeds 20 km/h for more than 2 min

**continuously or periodically: the sensor is damaged

11787590402

alternative NOx Sensor / emulator

11787590402

Bottom of car, passenger side, access form the car’s bottom

BMW | F10/11 with N53B30 series petrol engine

- Rough idle (cold and/or hot engine)

- Uneven run at mid/high loads

- Misfires and error messages about misfires

- Error messages about cylinder’s and/or bank’s fuel trim

- Problems with cold engine start

- Increased fuel consumption

- Restores normal operation of NOx system and fuel economy

- DOES NOT require NOx catalytic converter replacement

- Restores creation of cylinders individual and bank fuel adaptations for idle, mid/high loads, cold engine – smooth operation at all conditions

- Restores Stratified charge and Homogeneous lean fuel injection modes, regeneration, and desulfation of NOx catalytic converter

- Increased lifetime: average more than 300’000 km

Installation of NOXEM 402

Installation of NOXEM 402

Troubleshooting

Faq

Reason for replacement

Following NOx sensor error messages

12C104 NOx sensor, binary oxygen sensor: Line disconnection

12C108 NOx sensor, binary oxygen sensor: Short circuit

12C204 NOx sensor, linear oxygen sensor: Line disconnection

12C208 NOx sensor, linear oxygen sensor: Short circuit

12C304 NOx sensor, heating: Activation, line disconnection

12C308 NOx sensor, heating, activation: short circuit

12C401 NOx sensor, Plausibility, signal activity too low

12C501 NOx sensor, sensor poisoning: binary lambda signal too lean

12C502 NOx sensor, sensor poisoning: binary lambda signal too rich

12C504 NOx sensor, sensor poisoning: NOx signal too low

12C601 NOx sensor, operating readiness: Signal not available at start

12C602 NOx sensor, operational readiness: signal not available during operation

12C701 NOx sensor, heating: Heat output too low during starting

12C702 NOx sensor, heating: Heat output too low during operation

12C704 NOx sensor, heating: Supply voltage

12C801 NOx sensor, oxygen sensor before catalytic converter, plausibility: correlation fault

12C901 NOx sensor, adjustment: fault at start of charging phase

12CA01 NOx sensor, trailing-throttle check: binary lambda signal too rich

12CA02 NOx sensor, trailing-throttle check: linear lambda signal too rich

12CA04 NOx sensor, overrun test: NOx signal too low

12CA08 NOx sensor, overrun test: NOx signal too high

12CB01 NOx sensor, regeneration, nitrogen-oxide cat.: regeneration monitoring

12CB02 NOx sensor, regeneration, nitrogen-oxide cat.: time-controlled regeneration abort

12CC01 NOx sensor, oxygen sensor signal after regeneration, dynamics: Binary dynamic response too low

12CD01 NOx sensor, self-diagnosis: limit value 1 exceeded

12CD02 NOx sensor, self-diagnosis: limit value 2 exceeded

12CE01 NOx sensor, version: incorrect

CD8510 Lost Communication With NOx Sensor ‘A’

Following NOx catalytic converter error messages

180401 NOx catalytic converter: Efficiency below limit

Following live data

Stratified charge: disabled

The engine performs Homogeneous injection mode only

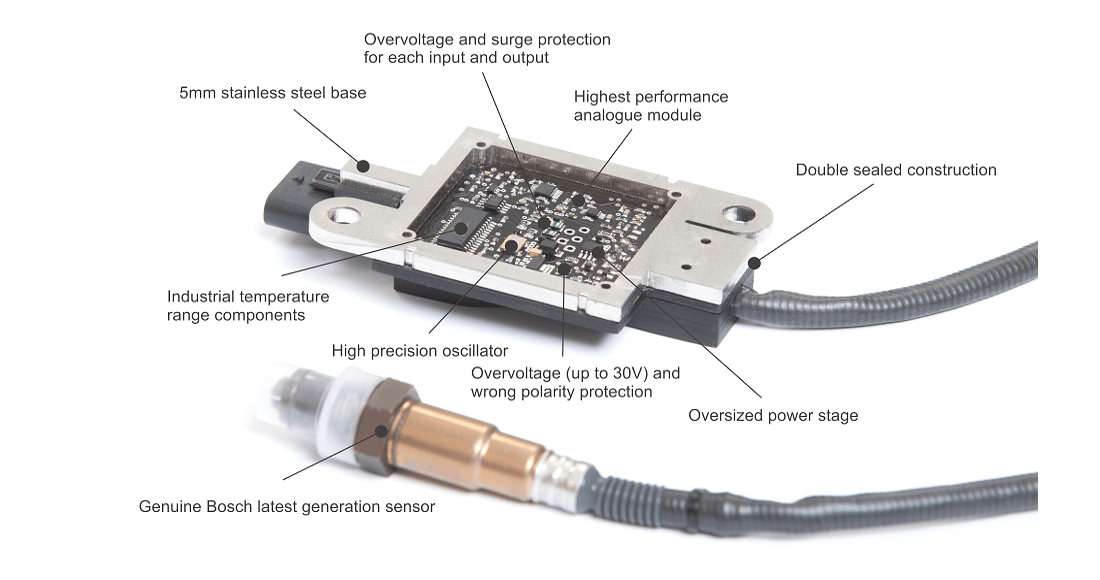

NOXEM series NOx emulator is built using the highest quality components

- Bosch’s latest-generation sensor is controlled and measured by ourselves developed analog control module which provides the highest accuracy of exhaust Lambda value. Now you can use NOx emulator Lambda data as reference

- Up to 30V overvoltage and wrong supply polarity protection guarantees the highest resistance to car’s onboard voltage spikes

- High precision reference frequency oscillator and industrial temperature grade components provide uninterruptible operation in a wide temperature range

- High power oversized sensor control stage reduce heating and facilitate the operation of the electronics module at high temperatures

- Double sealed construction with 5mm stainless steel base plate is a guaranty for long and safe operation in hard environment conditions

Electrical characteristics

- Power supply: +9.0 .. +16.0V DC

- Long-term over-voltage (1 hour): +24.0V DC

- Short-term over-voltage (1 second): +30.0V DC

- Wrong polarity short-term over-voltage (1 second): -30.0V DC

- Maximal current consumption (+14.0V DC; +25oC): 2.5A

- Average current consumption (+14.0V DC; +25oC): 0.8A

- Operation temperature: -40oC .. +105oC

Disclaimer

While using NOXEM 129 or NOXEM 130 NOx sensor emulator, the NOx level, emitted by the engine in some modes can differ from value, specified by the manufacturer. The user of the product assumes full responsibility for compliance with emission standards, valid in the country of use.

Attention!

NOXEM restores the normal performance of the NOx system, which is one of the main conditions for correct engine performance. Affirmation for the successful performance of NOXEM – no new error messages regarding NOx sensor in the memory of MSD80/MSD81. However, NOXEM does not guarantee the excellent performance of the engine, if the engine has others, not related to NOx system, defects and/or the required coding procedures, as described here and here, after installing NOXEM are not performed correctly/not performed at all. If you have doubts, that your choice to buy NOXEM, is correct, please, get in touch with Bimmerprofs via e-mail and include an exact description of your problem: screenshots of the INPA error message list, live data, etc.

Bimmerprofs offers help with online diagnostics for customers. More information here.

Attention!

Do not use aerosol type spray (brake cleaner, WD40 and similar) during replacement of the sensor! The fume of these sprays can damage the sensor! Remove the protective cap from the sensor directly before installation. If a spray is previously used, dry the surface using compressed air for several minutes.

MSD80 repair service

Starting form 199.00 EUR + p&p (50 .. 150 EUR across Europe)

Reason for repair

30BA DME digital motor electronics, internal failure

30BB DME digital motor electronics, internal failure

29CD misfirings, cylinder 1

29CE misfirings, cylinder 2

29CF misfirings, cylinder 3

29D0 misfirings, cylinder 4

29D1 misfirings, cylinder 5

29D2 misfirings, cylinder 6

(if these errors cannot be fixed replacing ignition coil; spark plug; injector)

2E18 ignition, cylinder 1

2E19 ignition, cylinder 2

2E1A ignition, cylinder 3

2E1B ignition, cylinder 4

2E1C ignition, cylinder 5

2E1D ignition, cylinder 6

Symtoms of relevant problem

The engine cannot be started

The engine works on 2 (N43) or 3 (N53) cylinders:

- no fuel for the damaged bank (cylinders 1;2;3 or 4;5;6: N53; 1;4 or 2;3: N43);

- no ignition for the damaged bank.

Error 30BA or 30BB cannot be cleared (re-appear)

Permanent misfires (after replacement of spark plug; ignition coil; injector)

Repair description

All (4/6 pcs) ignition coil drivers (transistors) and/or low-side injectors drivers are replaced with an improved models.

New drivers are characterized by:

- higher maximal allowed voltage (480 .. 600V instead of 250V)

- higher maximal allowed current (18.0 .. 50.0A instead of 8.9A)

- lower losses: lower voltage drop at ON state

- increased robustness: 300W power dissipation and overvoltage protection

F series. Diagnostics of NOx sensor

NOx sensors could be (and very often are) the reason, why the engines of the N53B30 engine family do not use a Stratified charge. Very often the error messages regarding these sensors are not recorded in the error message memory of DME even in cases of fundamental damage. Unfortunately, the diagnostics of the NOx sensors for F series vehicles (N53B30 petrol engine family) with the diagnostics equipment is very difficult. BMW has denied access to any pe of data, which corresponds to the NOx sensor.

These sensors have several hidden defects (detailed information read here), regarding which the error messages in the DME error message memory are not recorded, but the performance of the engine is impaired, Stratified charge – turned off. Some of them:

- problems with finishing the self-test/calibration. The sensor does not switch in Online mode and does not send live data;

- incorrect offset of NOx data. The sensor sends an increased amount of NOx and misleads DME regarding contamination and damage of the NOx converter;

- incorrect measurements of the exhaust temperature. The sensor misleads DME regarding the lowered temperature of the exhaust, DME does not switch the sensor in Online mode and does not use a Stratified charge.

Bimmerprofs offers diagnostics of the NOx sensors for the F series. During diagnostics, more than 17 parameters of the NOx sensor – static and live values, are inspected.

After diagnostics, you will receive the report regarding the performance of the NOx sensor.

Disclaimer. Very often the defects of the NOx sensor are sporadic. Performing a sensor performance check, the sensor will be tested for 15 minutes, turning it on and off for at least 5 times – it will be subjected to the thermal stress to make the detection of the defects easier. If the sensor will not indicate the required performance for even one time, these problems will be noted in the Diagnostics protocol. Unfortunately, even such a scrupulous diagnostics does not exclude rare cases, when the sensor is not able to switch in the Online mode or indicates other defects. Therefore, if the test result in the diagnostics protocol is marked as “suspicious”, we recommend replacing the sensor.

We will send the report as soon as possible with comments regarding incorrect or suspicious values, the report will be supplemented with images with marked incorrect values. We will give also suggestions and recommendations for required tests if the defect could not be recognized from the data sent.

We will help your car run smoothly again.

Example of Online diagnostics report

To each BMW enthusiast, we offer Online diagnostics

for N43/N53 engines!

How does ONLINE diagnostics works?

You are making screenshots using INPA and sending to us

We inspect all information and send back initial report

If necessary further inspection will be requested

Round 2 we inspect received information and give recommendations

We provide assistance until all the problems are soloved

What does it mean?

We will evaluate live data of INPA, sent to us by you, if necessary – will give recommendations for deeper research, if it would be required.

What do you have to do?

Prepare the screenshots of the required menus from INPA and send them to us together with a description of the problem.

(E81/E82/E88/E90/E91/E92/E93/E60/E61/E63/E64).

INPA MSD80 Loader 2.023 is necessary

We will send the report as soon as possible with comments regarding incorrect or suspicious values, the report will be supplemented with images with marked incorrect values. We will give also suggestions and recommendations for required tests if the defect could not be recognized from the data sent.

We will help your car run smoothly again.

Following systems will be checked (initial report)

1. Basic data

- Air consumption (air mass meter data)

- The temperature of the engine, coolant, oil, plausibility of these data

- The temperature of the exhaust system

- HPFP and LPFP pressures

2. Lambda probes

- Chemical activity

- Heating parameters

- Wide-band probes: proper Lambda readings

- Control probes: the ability of voltage generation

3. NOx sensor

- Proper data sending and status

- Offset value

- Wide-band and narrow-band Lambda data

4. NOx converter

- Status: normal or damaged (from live data)

- Amount of poisoning

5. Fuel mixture

- Offset type adaptations: amount, the deviation between banks

- Multiplicative type adaptations: amount, the deviation between banks

- Additional adaptations for a cold engine

- Lambda values and readings of Control probes (plausibility)

6. Injectors (data for each injector)

- Actual parameters: offset and multiplicative data

- Flow rate tests for low and high loads

- Flow rate tests for the cold engine

- Mechanical efficiency tests for Homogeneous injection (idle)

- Mechanical efficiency tests for Stratified charge injection (idle)

- Learnbits: status of completed/uncompleted adaptations

7. Analysis of error messages

- Status (active/passive)

- Importance and relationship with live data

- Determination of damaged component (errors + live data)

Based on initial information, additional systems (if necessary) will be tested:

1. Check-up of fuel system: jittering of pressures, leakage, fuel distribution in the fuel tank;

2. Test of VANOS: offset adaptations, confirmed position, jittering;

3. Lambda probes: tolerance of parameters, current leakage;

4. EGR valve;

5. Crankcase valve;

6. Ignition system: misfire counters (ELM327 adapter required);

7. Generator; IBS; power management;

8. DISA valves;

9. Electric fan;

10. Engine cooling flaps;

11. Electric water pump;

12. Thermostat with electric management;

13. Oil pressure management;

14. Throttle and accelerator pedal; etc.

Example of Online diagnostics report